EASY CHLOR

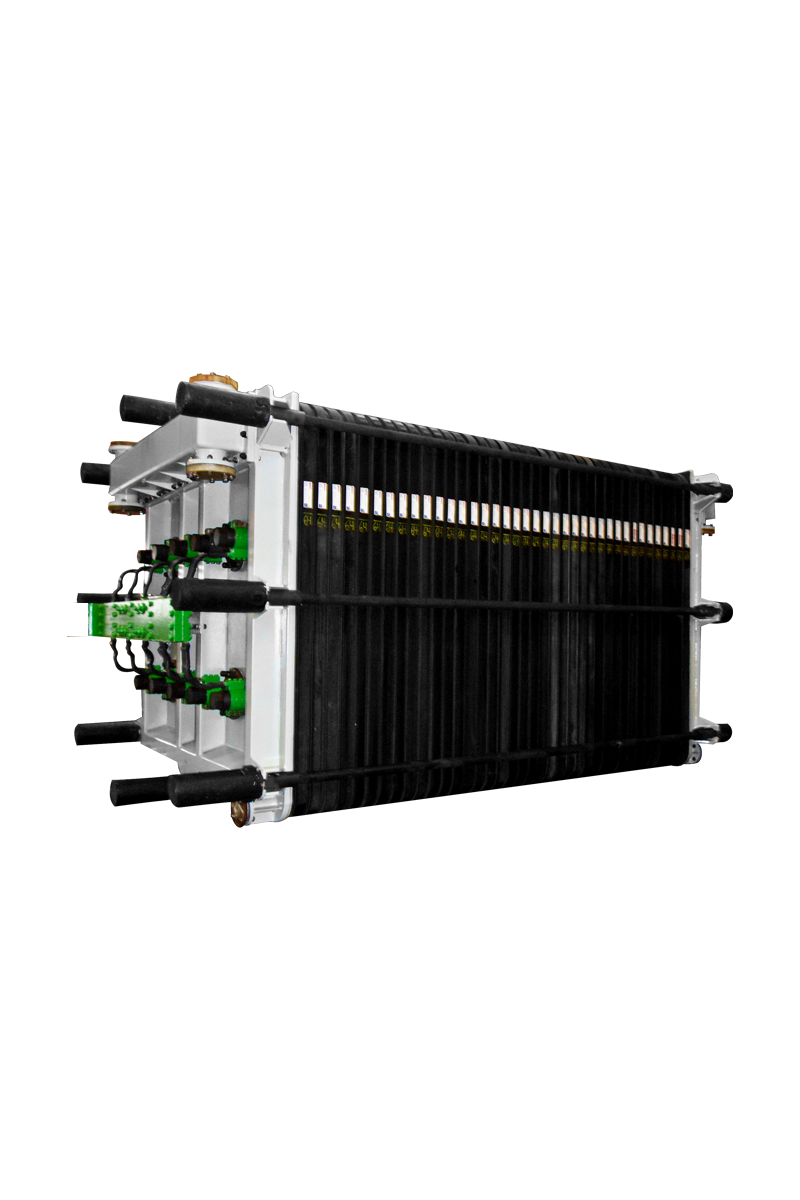

We recently presented our new Easychlor line on the market, which offers “turnkey” solutions for small industrial plants to produce chlorine and caustic soda (daily production up to a maximum of 10 tons).

These are independent production units, designed mainly for those geographical areas of the world that are still developing, as they do not require highly specialized technical skills and can be managed independently.

TELENE AND ITS APPLICATIONS

The thermosetting resins based on Dicyclopentadiene (DCPD), better known as Telene®, were introduced on the market in the early nineties by the company BF Goodrich of Cleveland (USA). They are now produced in Japan by the RIMTEC company and distributed in Europe by the Telene Sas company based in France.

The product is obtained by mixing two liquid components, of which the first contains a catalyst and the second a reaction activator. When these two components are mixed at high pressure using molding equipment with RIM (Reaction Injection Molding) technology, a polymer with particularly resistant physical and chemical characteristics is formed thanks to a metathesis process, which has found use in many industrial sectors.

For more technical information, visit www.telene.com

Since 1992 we have been supplying important components for electrolysers which are in service with the major European producers of chlorine and derivative products. Telene® is used in all types of electrolysers: with diaphragm, membrane and even mercury cathode technology.

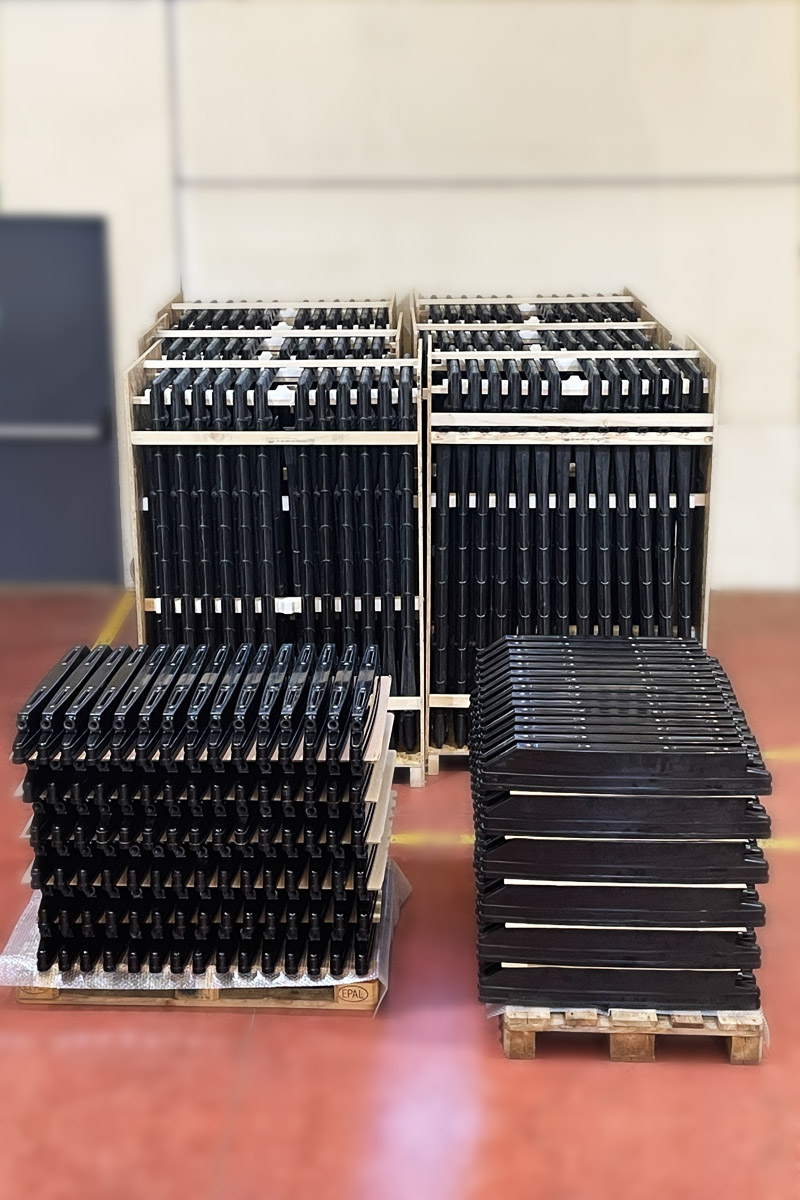

At the end of 2015, more than 50 plants in Europe replaced important components in ebonized steel with parts in Telene, in particular:

. Entry / exit heads

. Lids and Banks

. Accessory components

We have extensive experience and all the equipment to design and produce each component of the cells starting from existing drawings or parts.

RESEARCH AND DEVELOPMENT

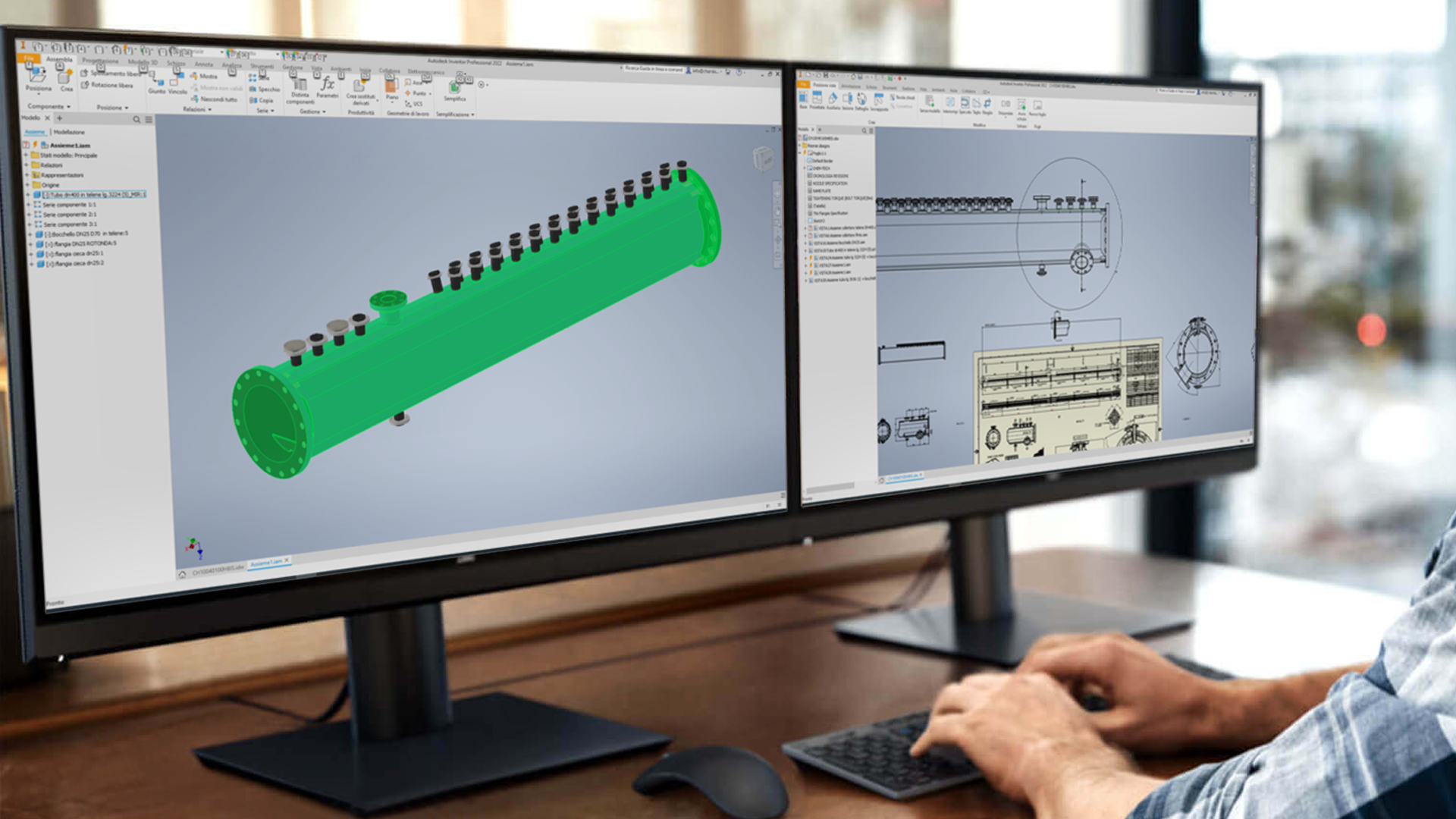

Our design team continuously develops new Telene products for use in chemical plants with particularly aggressive operating conditions.

The result of this research activity is the creation of state-of-the-art prototypes and components, mainly used in the electrolyzers of chlorine-soda plants.

All parts in Telene are obtained through RIM molding, starting with the creation of custom molds, designed with modern CAD / CAM stations, and collaborating closely with the end customer during the entire development phase of the new product.

The most recent example of R&D of a new product in Telene concerns the NEW UHDE COLLECTORS.

Below you can see the various stages of research and development of a new product, from its design to the moment in which it is used by the end customer.

ENGINEERING AND PLANTS

During all these years we have developed in-depth experience in the design and construction of plants for the treatment and remediation of residual gaseous effluents from production processes, such as organic synthesis, sulfonation, esterification, etc.

In this sector we put into practice the decades-long know-how acquired in the construction of equipment in corrosion-resistant materials.

Typical examples are: scrubbers, absorption columns, filters, reactors with their internal components.

For all these applications we are able to provide:

• Feasibility Study

• Preliminary Project | Executive project

• Procurement | Construction

These equipments are the main components of complete plants, intended for the treatment of gaseous effluents.

In particular:

• Absorption of chlorine, hydrochloric acid, sulfur dioxide and sulfur dioxide

• Acidic or alkaline gaseous emissions

• Process dust abatement

This is the main area of our business that has developed over the years, collaborating with the main players in the sector worldwide.

In particular, we design and build complete plants or plant sections for:

• Electrochemical production of chlorine, together with caustic soda or potash

• Preparation and purification of the brine

• Drying, filtration and liquefaction

• Production of sodium hypochlorite with prefabricated units in EASYCHLOR containers

• Use of chlorine for the production of ferric chloride and PAC (poly aluminum chloride)

We also design and build other equipment and components for the chemical industry, using corrosion resistant materials such as:

• Thermosetting resins based on DCPD (TELENE)

• Thermoplastic materials reinforced with glass fibers and resins

• Fluorinated thermoplastic materials: PVDF, E-CTFE, FEP, PFA, Teflon

• Metals such as titanium, nickel and special steels

CERTIFICATIONS

For us, quality is an absolute value, a philosophy that involves all business processes:

from design to production, from logistics to marketing.

The set of all the specific procedures that control the entire company organization constitutes the Chemtech Quality System.

View here our quality policy

► Certificates ISO 9001-2008 for the design and production of equipment for the chemical industry

► Qualified by the SYMALIT company for the construction of equipment with the use of thermoplastic materials: FEP, PFA, PVDF, E-CTFE

► Qualified by NOVEON for the construction of equipment and piping in C-PVC (CORZAN®)

► Qualified by the ECOVADIS company for the evaluation of our sustainability